RTV stands for Room Temperature Vulcanizing Silicone.

As Mechanics we know it more as the stuff that comes in a ton of different colors that you put on anything you don’t want to leak.

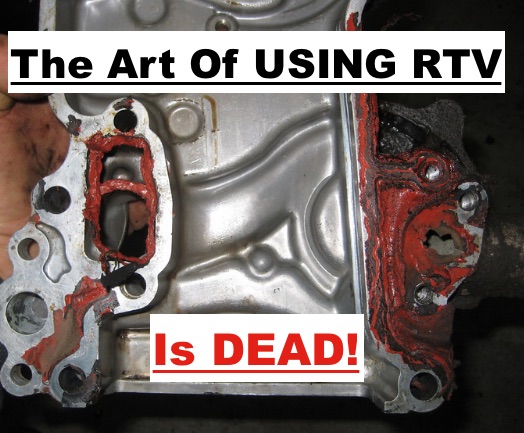

RTV is an essential part of car repair, and the well versed technician needs to understand how to use it correctly. Don’t use it correctly? Better start saving for a new engine. Here are the 5 top reasons why using RTV is a dying art.

1. Using Too Much

2. Using For the Wrong Application

3. Using The Wrong Type

4. Not Prepping The Surfaces

5. Not Trusting Gaskets To Do Their Job.

Have you ever thought (like me) a little bit more can’t be bad right? If anything it’ll help keep it from leaking again.

Or maybe it is leaking again because I didn’t follow that video I saw online where it said I was supposed to wait 20 minutes for the RTV to get tacky first. That must be it.

Hopefully, this article will clear up those misconceptions. Start using RTV like a pro again.

Table of Contents

1. Using Too Much

It breaks off inside the engine and forms hard little pieces that clog up oil ports, coolant passages, and cause damage to the engine. You may never even realize it, but using too much RTV on your oil pan gasket can very much lead to oil starvation and a blown engine.

Here it is explained by someone who rebuilds engines all the time and wants to warn us all about using way too much RTV. His stance is even more extreme, he thinks RTV should be banned from use.

From Another Mechanic Expressing His Distaste for Too Much RTV:

2. Using For The Wrong Application:

RTV that isn’t solvent based is not to be used around anything that touches gasoline. RTV isn’t going to stop something from leaking by simply just squirting it all over what is leaking (without taking it apart).

Also, I don’t know how much of it is marketing or not, but buy the RTV that is recommended for your use. If doing differential seals, buy the RTV that is resistant to gear oil. Exhaust? Get the red tape that is more heat resistant.

That is the first step of using RTV correctly in 2018. Just getting the right type.

Following the instructions on the box for proper usage / using the type of RTV that the factory service manual specifies for your application.

Another common thing mechanics do wrong / shouldn’t is applying RTV to paper gaskets (especially both sides). It is bad practice and can lead to the gasket failing sooner than it should.

Watch this video. He has seen many paper gaskets fail due to putting RTV on both sides of the gasket.

What Should You Use On Paper Gaskets? Not RTV!

This is a great time to use Copper Spray or other spray made to be sprayed directly on the gasket.

It is also the proper time to bust out my favorite product (links to Amazon).

Why is it my favorite? Because it has the word “aviation” in the title.

What makes it different from RTV is that it doesn’t harden, it resists gasoline, works up to 400 degrees Fahrenheit. It also much thinner and much won’t harden as RTV does.

For exhaust gaskets and some other metal type gaskets you may want to look into using a spray type gasket coating. I would avoid using this on a head gasket personally, as I would like to believe the company making the head gasket doesn’t want me changing its properties by coating it in a copper spray.

The two best kinds I like are the Permatex Spray A Gasket, and this K & W Copper Coat Gasket Spray. Both links open to Amazon to check to price.

Here is How To Apply Spray Gasket Sealers Directly From Permatex:

3. Using The Wrong Type of RTV Or Sealant

Like anything being sold today in the automotive market, there are hundreds of options, if not thousands.

Here is how to know which RTV to choose:

- Does your application call for an Anaerobic Curing RTV?

- Then you must use an Anaerobic RTV which is much less common to see, but only cures in the absence of oxygen.

- It can be confusing exactly what the difference is between regular RTV and Anaerobic. I can’t claim to know the exact scientific difference, but it does seem some car repair factory service manuals will specifically request you to use Anaerobic RTV.

- One of the most highly reviewed and well liked Anaerobic RTV’s is this Permatex 51813 Anaerobic Gasket Maker (links to Amazon).

- People also seem to really like using the Anaerobic RTV in place of regular RTV.

- It won’t cure hard like regular RTV if you get too much on the gasket (it needs to be in an oxygen-free environment to cure).

- Meaning it won’t clog up oil pumps, passages, or water pumps because it will stay liquid if you use too much.

- Here are some people that swear by using an Anaerobic RTV instead of a typical RTV like Ultra Grey.