How to use diclofenac. The app is https://newzealandrx.co.nz/buy-cialis-soft-new-zealand.html your one-stop-shop for all things convenience.

Ok, so you somehow rounded a bolt or fastener and it is in a tight spot. You are having trouble getting access to it and want to know how the professionals attack rounded bolts and nuts in tight spaces?

You came to the right place because I also wanted to be sure I knew all the strategies to remove rounded bolts and nuts in tight spaces. So, I did a TON of research and came up with the post of all the best ways to remove rounded fasteners on cars and trucks.

Really these are all methods you should know. These are all the tools you should have in your toolbox.

Methods change depending on access and where the rounded bolt is located. For example, if you are working anywhere near fuel lines or gasoline DO NOT use any method involving a torch or heat. As always with car repair, common sense is worth more than a big bag of tools.

Table of Contents

How To Remove Rounded Nuts & Bolts In Tight Spaces:

First, some quick conclusions:

- Always use heat if possible. Get the bolt or nut red hot with a torch before trying to remove it.

- Also, spray penetrating oil and let it soak in. A mix of ATF and Acetone works as well (click here to read how to mix your own penetrating oil).

- Avoid rounding off bolts by using 6-point sockets and high-quality wrenches. Cheap sockets and 12 point sockets and wrenches are more likely to round off nuts and bolts.

- Open-ended wrenches are not for breaking big bolts or tight fasteners loose. Use the proper socket or the box end of the wrench to avoid slipping.

Best Methods for Removing Rounded Nuts & Bolts in Tight Spaces:

- Use a Damaged Bolt Remover Socket Set– the best is the Irwin Damaged Extractor Set

on Amazon.

- Hammer on a smaller socket and remove the rounded bolt.

- Use Vice Grips and grab the fastener as tight as possible and remove normally. This will not work on bolts torqued down super tight or super badly rounded bolts. You can easily do more harm than good with vice grips if you try to remove a nut or bolt that is torqued super tightly with vice grips.

- Use a set of “lock-on” sockets if you don’t have a damaged bolt extractor set.

- Knipex Cobra Pliers or similar strong grip pliers and remove.

- Use a Flank Bite Combination Wrench Set (these work great for tight spaces on wrenches can fit).

- Air Hammer (Rivot Gun) with super long chisel bit bite into the side of the rounded bolt and hammer it loose.

- Turn it liquid with an oxy-acetylene torch (this is more for professionals with experience).

Removal Guide With Photos:

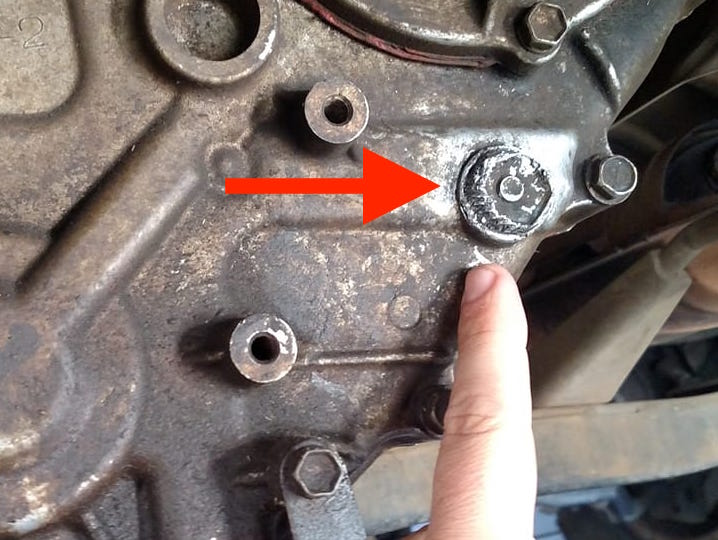

Basically, if you are able to fit a socket on the bolt then the absolute best method is to use these damaged fastener type sockets they make specifically for removing rounded nuts and bolts. You find one that just won’t quite fit over the head of the bolt or nut and then you pound it on with a hammer (as straight as possible). Get it flush with the bolt then remove as you normally would. Using an impact wrench is best just be gentle with the trigger to avoid shearing the bolt head off.

Many professional mechanics own the Irwin Extractor Socket Set and really swear by it. There are many different brands including tool truck brands that cost hundreds of dollars, but I really do think the Irwin extractor sockets are PERFECT for the professional mechanic or DIYer alike. Click the link above to check for the best prices on Amazon for a set.

You basically just need to hammer on one of those sockets and then zip it off with your impact wrench or work it off with a ratchet. If the bolt is rusty, super tight, or to just be safe– soak it in penetrating oil and torch it until it gets red hot.

Why Using Vice Grips Isn’t Always The Best Solution:

DO NOT try multiple times with vice grips if you are unsuccessful. They are an okay way to attack a rounded off bolt in a tight space if it is relatively small (less than 14mm as a general rule) and not torqued past say (30-40ft-lbs). Anything more and likely the vice grips will slip and cause more problems.

The best thing to do when you see a bolt starting to round is to take a break and rethink your strategy. Once you own some extractor sockets I guarantee you will immediately grab for those and forget the vice grips.

Even Tighter Clearance, Rounded Bolt With No Room for Socket?

Maybe you are battling super tight clearance and there is no chance you can fit a socket and ratchet on the rounded bolt or nut. Here are some more strategies for removing SUPER tight clearance bolts and nuts. You will need some specialty tools for most of these strategies, but if you have a compressor handy you will grow to love these tools as well.

Air Hammer + Long Chisel Bit:

- Start by chiseling straight down into the bolt to allow yourself a bit to “bite” into with the chisel.

- Angle the air hammer with chisel bit in the direction you want the bolt to go.

- Carefully start hammering and once the bolt begins to spin keep going until you need to reposition the chisel.

- Repeat steps 1-3. Watch this video if you are confused:

Knipex Cobra Pliers Or Similar (Grab n Go):

- These work better than vice grips (typically) but also shouldn’t be used on super tight fasteners.

- Grab the fastener with the pliers, get a good grip, and work it out (simple as that).

- Knipex Cobra pliers or Aligator pliers are some of the best pliers for mechanics for all types of jobs.

- Penetrating oil & heat are your friend as always. Watch video here to see in action:

Welding a Nut or Bolt on the Rounded Fastener:

- Weld a nut or bolt to the rounded off the fastener.

- Remove as you normally would.

- Re-weld if it snaps or breaks.

- Obviously, having skills as a welder come in handy here but this is a more “pro” way of removing rounded nuts and fasteners. Especially SUPER tight ones.

Watch this video if to see welding removal for rounded nuts and bolts in action– great tutorial:

Grinding Flat Spots Then Using Another Socket:

- With a cutoff wheel and a steady handy grind, the rounded off parts of the bolt or nut until you can fit a socket back on.

- Remove like normal.

- This method is likely slower and not as effective as just using rounded bolt remover extractors. But sometimes the bolt is too big and you don’t have a damaged fastener socket that fits it– in which case this strategy may work.

Why Rounded Off Bolts and Nuts Happen In The First Place:

Typically people round off nuts and bolts by using the wrong tools for the job. You need sockets that are right for your specific fasteners to work. Read my post here on metric vs. sae and realize why it is super important to use the right socket with the right fastener type (metric or standard).

The most common places beginner or DIYer mechanics round off bolts? Oil pan drain plugs.

Why? Because this is typically the first place the DIYer or YouTube inspired mechanic starts his/her career wrenching on their own car. Also, the most common reason mechanics have problems with rounding bolts is because of the previous person working on the car not torquing down the bolts correctly. This is common with people changing their own oil and torquing down the oil pan drain plug bolt WAY too tight.

To avoid this use a torque wrench and learn about how to get a feeling for torque down.

What is the first job most people (including myself) first ever did? Using doing their own oil change.

With what tools? Usually the adjustable wrench from your dad’s old carpenters tool box. An adjustable wrench should almost NEVER be used on any drain plug bolts, and especially in the beginner’s hands, is a likely recipe for disaster.

Conclusion & Related Questions:

Buy the right tools for removing bolts and nuts and have the right strategies. If you notice a bolt is rounded or starting to round, then you should immediately stop and change direction.

Impact wrenches, especially having a set of cordless impact wrenches, will help you immensely as the hammering effect they use helps break bolts and nuts loose.

You should basically never use vice grips or adjustable wrenches on any drain pan bolt. Use the right socket, and typically 6 point sockets should be used on any regular hex head fastener. 12 point sockets tend to round more bolts than need be, and you should only need them when the fastener requires a 12 point socket.

Owning an extractor socket set is absolutely essential to removing already rounded nuts and bolts. They aren’t very expensive at all and will save you SO much time. You can also use any of these strategies listed above, and you should learn all of them to be a well-rounded mechanic (no pun intended).

Remember to always replace any bolt that has any signs of being rounded off! NO BOLT OR NUT should ever be put back that has been removed with extractor type sockets or grabbed with vice grips. Any marring on the sides of the bolt can come back to haunt you down the road.

Related Questions:

How do I remove a stripped Allen head bolt in a tight space?

Answer: Use an easy out extractor set to remove stripped Allen head bolts. They are absolutely the best way to remove stripped out Allen head bolts and will work on even the smallest fasteners. You can also drill them out, but if you have them always use left spinning drill bits.

That is because instead of using a regular drill bit which may actually push the broken part of the bolt deeper and tighter, left-handed drill bits will actually work to remove the stripped bolt or broken off part. They are absolutely essential to making removing broken off bolts or Allen head bolts easier. You do not want to ever cause the bolt to be tighter simply by drilling in the wrong direction with the wrong bit!

How do I remove a stripped out the bolt in a tight space?

Answer: I assume you mean the head is rounded off on the bolt, and you should remove it by using a damaged socket extractor set. You can also use a torch, weld a nut to the top, drill it out, or grab it with Knipex Cobra style pliers.

The main thing you want to avoid is rounding it off, even more, so make sure you attack it as soon as you start feeling it round off. Heat, penetrating oil, and the correct tools are your best friend.

How do I remove a stripped out oil pan drain plug bolt?

Answer: Use an extractor socket set that fits just barely over the drain pan plug bolt. The best is if you have to hit the socket onto the bolt with a hammer (go gently and get the socket as straight and flush on the bolt as possible). Use an impact wrench to remove the rounded or stripped oil pan bolt on the lowest setting and only going higher if it doesn’t come off.

Remember using a torch for heat and penetrating oil are also your friends in this situation. The absolute worst case scenario is drilling out the oil pan drain plug bolt and retapping new threads for a larger oil pan drain plug bolt. This should be done by a professional unless you are really confident drilling into an oil pan (remember metal shavings in oil=bad).

What are the best extractor socket sets for large bolts and nuts?

Answer: The best thing to buy for those larger bolts and nuts that are rounded off is actually locking lug nut removal sockets. These sockets are designed to removing those locking lug nuts you see on some cars. They are typically round lug nuts with an indentation that only a special socket can remove (typically inside the car in the glove box) these constantly get lost and mechanics need a way to remove the locking lug nuts.

These sockets are just like the damaged bolt sockets in that they just bite into the bolt or lug nut and then remove it. You should always replace whatever bolt or nut you remove with these damaged bolt extractor type sockets as they destroyed the bolt’s face.